- Comes with the necessary equipment such as standard tap, advertisement stuff or printing, etc. is not included.

- Delivery includes a Gastro apron with three pockets for wallet, service accessories, etc.

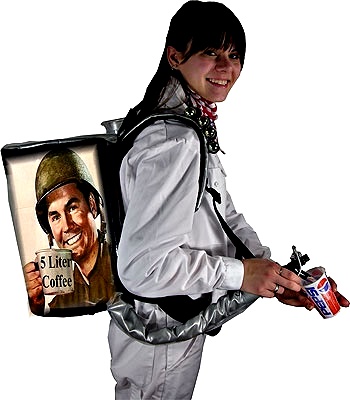

- The "small" Premium 5-liter drink backpack is a multifunctional mobile beverage dispenser.

- Depending on the model equipment, suitable for serving carbonated drinks, hot/cold.

- This is the small version among the universally functional beverage backpacks.

- It can be used for all carbonated and still beverages, hot and cold.

- It is suitable for easy and fast beverage service!

- The system has a rock-solid construction with low dead weight and good insulation

- (up to 2 hours and more).

- The Premium 5-litre fulfills all the requirements of a professional as well as mobile drinks service.

- Has a 5-Litres container storage for carbonated beverages

It provides support to mount a promotion flag where a weatherproof foil bag takes two A4 sized inserts in any prominent colour.

- The Premium 5-Liter is particularly suitable for indoor applications.

- Expansion joint, one-hand nozzle, drink /pre-mix, complete with pipe, insulation, jacket and connection part,

- Article Premium 5 litre "for carbonated beverages.

- Particularly well suited for fast, uncomplicated beverage Service.

A large vinyl display cover allows quick change!

- The Premium 5-Liter is particularly suitable for indoor applications.

- Expansion joint, one-hand nozzle, drink /pre-mix, complete with pipe, insulation, jacket and connection part.

- The backpack drink dispenser consists of a hand-operated drinks air pump and steel casing to generate the dispensing pressure.

- It can be used for strongly flavored drinks like mulled wine, coffee, fruit tea, cocktails, etc.

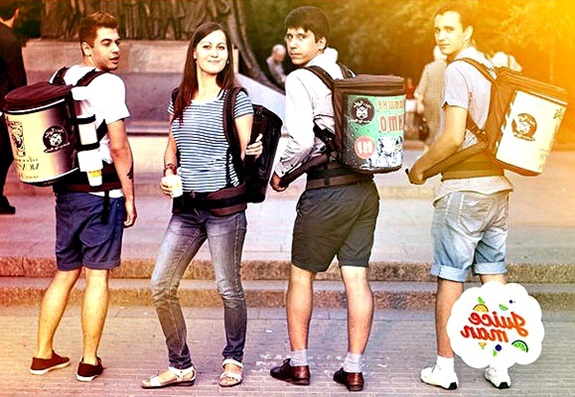

It can be used in fairs, clubs, company parties, product tastings in supermarkets, promotions and department stores or shopping centers, or private festivities.

- The Premium Tap

- Composed of the pipe, insulation, jacket, and tank connection part, Hand-operated air pump (as pressure booster only if required), steel housing.

- Drink containers can also be used to cater to cleaning, odor, and deposits.

- Furthermore, this item has moderate insulation, up to max. 2 hours (depending on the outside temperature).

- We recommend using it for cold and hot drinks because of its sound insulation.

- When used with hot drinks, or beer, beverage containers can quickly inflate.

Utilizes a durable steep AFG container with 5-litres of capacity, and the container and the external pipeline is well insulated to maintain the actual temperature and the quality.

If pre-filled drinktanks are used, make sure they are kept chilled in a container with crushed ice or refrigerator (see at 33 degrees).

Drink Dispenser Backpack Video

5 Litre Drink Backpack for Mobile vending, from concerts to sporting events to street festivals.

- If there is a problem with liquid dispensing or the liquid is not coming out

- Check the connection of the Dispensing Hose!

- See if it is properly connected to the backpack/container.

- Check If the pipeline to the tap is adequately connected to the outer valve.

- Gastro-Vendor apron with 3 pockets to store accessories etc.

- It provides support to mount a promotion flag where a weatherproof foil bag takes two A4 sized inserts in any prominent colour.

5 Liter Drinkbackpack Video

It is designed and efficiently made in Germany. Backpack drinks dispensers from Rocket-Packs can also be used to distribute beverage cans and bottles. However, we are genuinely focusing on drink dispensers that can be used to distribute either hot or cold drinks.

- The drink backpack cover is ergonomically designed and made from robust and weatherproof materials.

- Smaller size takes smaller storage and is easier to carry and there is not much load.

Reliable, robust drink backpack with low weight and good insulation.

- The beverage container has capacity of 5-litres and the beverage is dispensed naturally without any pressure generated.

- It is optional to include standard or premium tap

- Gastro apron and Promotion Flag are also available.

- The material used is very robust and weatherproof truck tarpaulin

- It provides insulation for up to 2 hours or more (depending on ambient temperature)

- The dimensions are H 36 x W 31 x D 28 cm

- Weight without beverage content is 4.0 Kg

- The advertisement space has dimensions of H 30,5 x W 64,5 cm

- Has a transparent cup dispenser that takes EW cups of 90 -150 ml.